Abrasive Blasting

Abrasive Blasting for Industrial Strength Coatings!

Abrasive Blasting "Sandblasting"

Neumann Industrial Coatings takes pride in offering top-notch abrasive blasting services in our advanced facility in Currumbin, on the beautiful Gold Coast.

Our skilled professionals use state-of-the-art equipment to blast surfaces with steel grit or crushed glass media, depending on the specific requirements of your project. Our team has years of experience in the industry, and we strive to deliver the best results for every project we undertake.

We carefully evaluate each project and suggest the best abrasive blasting technique to meet your unique needs.

Steel Grit Abrasive Blasting

Steel grit blasting is a robust and highly effective process for cleaning, stripping, and removing rust from metal surfaces.

It is the go-to solution for heavy-duty industrial applications, marine and automotive maintenance. The secret to a successful steel grit blasting operation is choosing the right grit size for the job. Neumann Industrial Coatings uses cast steel angular grit, specially heat-treated to produce high-quality results. Our GL 40 steel grit, which measures approximately 0.5mm, is harder than general-purpose steel grit and is perfect for heavy descaling and surface preparation tasks.

It quickly removes rust, corrosion, and other stubborn surface contaminants, leaving you with a clean, polished finish.

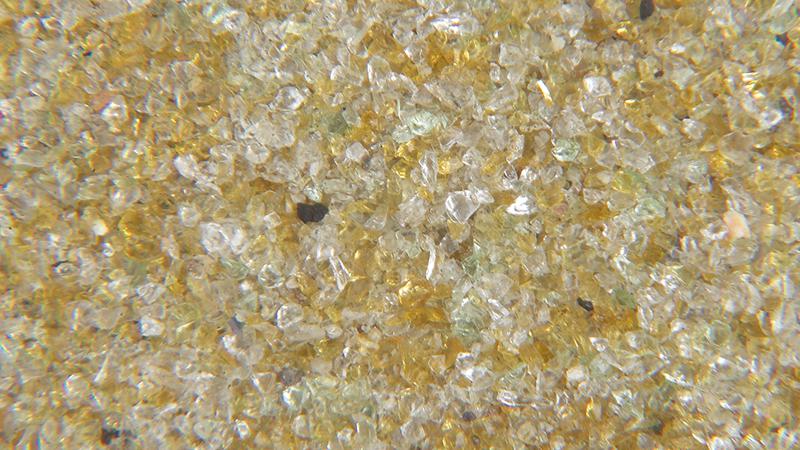

Crushed Glass Abrasive Blasting

If you’re looking for an eco-friendly abrasive blasting solution that also saves you time and money, consider crushed glass media!

This abrasive material is entirely made from recycled glass and features sharp, angular particles that quickly remove even the toughest coatings like epoxy and paint. It is also much lighter than traditional slag abrasives, which means you can get more blasting done with less material, saving you up to 30-50% on your overall consumption.

So, if you want a powerful, sustainable blasting solution that delivers excellent results every time, give crushed glass media a try!

Quality Assurance

At Neumann Industrial Coatings, we take quality seriously. We understand that a high-quality finish is essential for the longevity of your industrial equipment or infrastructure.

That’s why we have a rigorous quality assurance process to ensure that every project meets our strict standards of excellence. Our quality assurance process involves multiple checks and inspections throughout the project, from surface preparation to the final coat.

We use advanced testing equipment to measure coating thickness, adhesion, and other critical factors to ensure that the finished product meets or exceeds your expectations.

Australian Standards

- AS1627.4-2005 – Metal finishing – Preparation and pretreatment of surfaces – Part 4: Abrasive blast cleaning of steel

- AS1627.9-2002 – Metal finishing – Preparation and pretreatment of surfaces – Part 9: Pictorial surface preparation standards for painting steel surfaces

All Neumann Contractors personnel are competent and suitable trained, qualified and supervised.

Our Abrasive Blasting is fully compliant with:

Rust Grades and Classes of Blast Cleaning

According to AS 1627.9 – Metal finishing – Preparation and pretreatment of surfaces – Pictorial surface preparation standards for painting steel surfaces, there are four initial rust grades, depending on the amount of mill scale and rust. The worst grade of rust that is evident on the steel surface is recorded and treated accordingly. The four Rust Grades are:

GRADE A

Steel surface covered completely with adherent mill scale and with little if any rust.

GRADE B

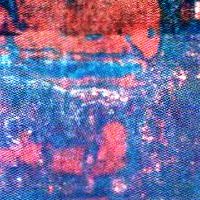

Steel surface, which has begun to rust and from which the mill scale has begun to flake.

GRADE C

Steel surface on which the mill scale has rusted away or from which it can be scraped, but with little pitting visible to the naked eye.

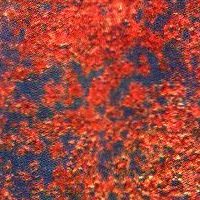

GRADE D

Steel surface on which the mill scale has rusted away and considerable pitting are visible to the naked eye.

Classes of Blast Cleaning

(Abrasive Blasting) – As defined in AS 1627.9 – Metal finishing – Preparation and pretreatment of surfaces – pictorial surface preparation standards for painting steel surfaces, there are also four classes of Blast Cleaning, which are:

Sa 1 (Brush Blast)

Light blast cleaning. The surface shall be free from visible oil, grease and dirt, and poorly adhering mill scale, rust, paint coatings, and foreign matter when viewed without magnification. The appearance corresponds to the prints designated Sa 1 in AS 1627.9. NOTE: Mill scale, rust or paint coating is considered poorly adhering if removed by lifting with a blunt putty knife.

Sa 2 (Commercial Blast)

Thorough blast cleaning. When viewed without magnification, the surface shall be free from visible oil, grease and dirt, from most mill scale, rust, paint coatings and foreign matter. Any residual contamination shall be firmly adhering (see note to Sa 1). It corresponds to the appearance of the prints designated Sa 2 in AS 1627.9.

Sa 2½ (Near White Metal)

Comprehensive blast cleaning. When viewed without magnification, the surface shall be free from visible oil, grease and dirt, and shall be free from mill scale, rust, paint coatings and foreign matter. Any remaining contamination shall show only as slight stains in the form of spots or stripes and correspond to the prints designated Sa 2½ in AS 1627.9.

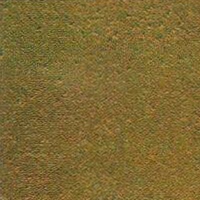

Sa 3 (White Metal)

Blast cleaning to visually clean steel. When viewed without magnification, the surface shall be free from visible oil, grease and dirt, and shall be free from mill scale, rust, paint coating and foreign matter. It shall then have a uniform metallic colour and correspond to the prints designated Sa 3 in AS 1627.9.

Note: The images shown above are indicative only; they show the results of abrasive blasting to Grade C rusted steel surfaces.

Neumann Industrial Coatings predominately perform abrasive blasting services to a class Sa 2½ (Near White Metal) and Sa 3 (White Metal)

More Information about Abrasive Blasting at Neumann Industrial Coatings:

Surface preparation is made easy with Neumann Industrial Coatings’ abrasive blasting services.

Abrasive blasting is a surface preparation process that involves the use of tiny abrasive particles propelled at high velocity to clean, strip, or etch surfaces. This process is commonly used in industrial applications to prepare surfaces for painting, coating, or to remove corrosion, rust, or other unwanted materials. Neumann Industrial Coatings is a trusted name in the industry, offering state-of-the-art abrasive blasting services to its clients. This essay will explain what abrasive blasting is, its benefits, and how Neumann Industrial Coatings can help.

What is Abrasive Blasting?

Abrasive blasting is a process that involves propelling abrasive particles at high speeds onto a surface to clean, roughen, or shape it. This technique is widely used in various industries, such as construction, automotive, marine, and aerospace. It can be used for various applications, from preparing surfaces for painting or coating to removing rust, old paint, or other unwanted coatings.

There are various types of abrasive blasting methods, including sandblasting, steel grit blasting, and crushed glass blasting. Each method has unique properties and is best suited for specific surfaces and applications. For example, steel grit blasting is often used for heavy industrial plant and equipment, marine vessels and structures, truck bodies, or trailers. At the same time, crushed glass is more commonly used for lighter steels, galvanized steel, stainless steel, or aluminium.

Benefits of Abrasive Blasting:

Abrasive blasting offers several benefits for industrial applications, including:

- Efficient Surface Preparation:

Efficient surface preparation is critical to the success of any project that requires surface coating, painting, or restoration. Abrasive blasting is one of the most efficient surface preparation methods available. It quickly and effectively removes contaminants, rust, and old coatings from surfaces, leaving them clean and ready for further treatment.

The use of abrasive blasting eliminates the need for manual cleaning, which can be time-consuming and labour-intensive, especially when dealing with large surface areas. With abrasive blasting, the process can be automated, reducing the time and labour required to prepare the surface.

Abrasive blasting also ensures that the surface is evenly cleaned, removing all contaminants and leaving a consistent surface profile. This ensures the coating adheres properly to the surface, creating a long-lasting, durable finish. In contrast, manual cleaning may leave behind small pockets of contamination, which can compromise the integrity of the coating and reduce its lifespan.

Moreover, abrasive blasting provides an efficient way to remove rust, corrosion, and other surface defects. These issues can significantly compromise the structural integrity of the surface, making it more susceptible to further damage and failure. By removing these defects, abrasive blasting helps to restore the surface to its original condition, increasing its lifespan and durability.

- Cost-effective:

Abrasive blasting is a cost-effective solution for surface preparation for a variety of reasons. One of the main reasons is its efficiency in removing old coatings and rust, which reduces the amount of labour and time required for the job. This translates to significant cost savings, especially for large-scale projects. Abrasive blasting can remove coatings and rust in a fraction of the time it would take with traditional methods, such as scraping or sanding.

Additionally, abrasive blasting is a precise and controlled process, meaning there is less material waste than other methods. This not only saves on material costs but also reduces the amount of waste that needs to be disposed of, which can be expensive.

Furthermore, abrasive blasting is a one-step process that can remove multiple coatings and rust layers, eliminating the need for additional steps and products to complete the job. This saves on product costs, time, and labour.

Finally, abrasive blasting can prolong the lifespan of equipment and structures, which can save on replacement costs in the long run. By removing rust and coatings, abrasive blasting helps to prevent further corrosion and damage, which can lead to costly repairs or replacements. Regular maintenance through abrasive blasting can help to extend the life of equipment and structures, resulting in significant cost savings.

At Neumann Industrial Coatings, we understand the importance of cost-effectiveness in surface preparation. That’s why we offer a variety of abrasive blasting services that are tailored to each client’s specific needs and budget. Our team of experienced professionals uses state-of-the-art equipment and techniques to ensure that every job is done efficiently, effectively, and within budget. We also offer competitive pricing and flexible scheduling to accommodate even the most demanding projects. With our abrasive blasting services, our clients can be confident they are getting the most cost-effective solution for their surface preparation needs.

- Environmentally friendly:

Abrasive blasting is also environmentally friendly due to the fact that it is a dry process that produces no harmful chemicals or waste products. Unlike traditional cleaning methods that use chemicals or solvents, abrasive blasting relies solely on the use of an abrasive media and air pressure. This means that there is no need for any harmful chemicals or solvents to be used, reducing the risk of environmental pollution.

Furthermore, abrasive blasting can be performed with recycled abrasives, such as crushed glass or steel grit, reducing the need for new materials and minimizing waste. At Neumann Industrial Coatings, we use 100% recycled crushed glass media in our blasting services, reducing waste and costs for our clients.

Another environmentally friendly aspect of abrasive blasting is that it removes surface contaminants, such as rust and paint, from metal surfaces, allowing for proper disposal and preventing the release of pollutants into the environment. This is especially important when working on marine vessels or equipment that may be in contact with water, as the removal of rust and other contaminants prevents the contamination of waterways.

Finally, abrasive blasting is also more efficient than other cleaning methods, which can take longer and require more energy and resources. The efficiency of abrasive blasting means that less energy and resources are required to complete the job, further reducing the environmental impact of the process.

Overall, abrasive blasting is an environmentally friendly option for surface preparation and cleaning that reduces waste, eliminates the use of harmful chemicals, and is more efficient than other methods.

Neumann Industrial Coatings Abrasive Blasting Services:

Neumann Industrial Coatings offers a wide range of abrasive blasting services to meet the needs of its clients. These services include:

- Steel Grit Blasting:

At Neumann Industrial Coatings, we provide our clients with high-quality steel grit blasting services. Steel grit blasting is a widely used method of abrasive blasting that effectively removes rust, paint, and other coatings from metal surfaces. This process uses steel grit, a cast steel angular grit produced by crushing specially heat-treated oversize shot pellets.

One of the main advantages of steel grit blasting is its ability to clean and strip metal surfaces effectively. The grade or size of the grit determines the ultimate finish of the surface. We typically use a GL 40 steel grit (about 0.5mm), which is harder than general-purpose steel grit and particularly suited to heavy descaling and surface preparation requirements. This type of grit cleans rapidly to give a clean finish to all surfaces.

Our expert staff can determine the most appropriate method to suit your particular application and desired finish. We can perform steel grit blasting on heavy industrial plant and equipment, marine vessels and structures, truck bodies or trailers, and more. Our process is completed up to Australian Standard class Sa3 (White Metal) or as required.

In addition to being efficient, steel grit blasting is also cost-effective. Using steel grit ensures the process is quick and precise, reducing labour costs and increasing productivity. Moreover, since steel grit can be recycled, the approach is more eco-friendly than other methods that require the use of disposable materials.

We understand that every project is unique, and our team of professionals has the knowledge and experience to handle a wide range of surfaces and coatings. Whether you need to prepare metal surfaces for repainting, remove rust, or clean heavily soiled equipment, our steel grit blasting services can provide the desired results.

At Neumann Industrial Coatings, we are committed to providing our clients with the highest level of service, quality, and professionalism. We take pride in delivering efficient and cost-effective solutions for our clients’ abrasive blasting needs, and our steel grit blasting services are no exception. Contact us today to learn more about how we can assist you with abrasive blasting needs.

- Crushed Glass Blasting:

At Neumann Industrial Coatings, we offer crushed glass abrasive blasting services, a highly effective and eco-friendly method for surface preparation, cleaning, and removing coatings on metal surfaces. Crushed glass abrasive blasting involves propelling tiny particles of crushed glass at high velocity onto a surface to clean, strip, and remove rust or other contaminants.

One of the significant benefits of crushed glass abrasive blasting is that it is a 100% recycled material, making it an environmentally friendly option for surface preparation. It also produces less dust than traditional sandblasting, making it safer and easier to clean up.

Crushed glass abrasive blasting is highly versatile and can be used on various materials, including steel, stainless steel, aluminium, and galvanized steel. The angular particles in crushed glass allow for aggressive surface profiling, making it highly effective at removing coatings such as epoxy, paint, alkyds, vinyl, polyurea, coal tar, and elastomers.

Our team of experts at Neumann Industrial Coatings can determine the most appropriate grade or size of crushed glass based on the desired finish and the application. We typically use a range of grades, from fine to coarse, depending on the project requirements.

Crushed glass abrasive blasting also offers a range of benefits compared to other blasting materials. It is much lighter than many slags, which allows for increased consumption efficiency and production time, with up to 30-50% less glass grit used. This reduces the overall project cost and makes it a cost-effective option for surface preparation.

In addition, crushed glass abrasive blasting is a low-dusting process, making it safer and easier to clean up after completing the project. It is also non-toxic and non-hazardous, which means it is safe for workers and the environment.

Neumann Industrial Coatings is committed to providing high-quality, efficient, and environmentally friendly surface preparation services. Our team of professionals is highly skilled and experienced in using crushed glass abrasive blasting to achieve the desired finish and meet the project requirements. Contact us today to learn more about our crushed glass abrasive blasting services.

- Professional Expertise:

At Neumann Industrial Coatings, we take pride in our professional expertise in abrasive blasting services. Our team is highly trained and experienced in utilizing the latest technology and techniques to provide high-quality and efficient services.

We understand that each project is unique, which is why we work closely with our clients to determine the most appropriate abrasive blasting method to achieve the desired finish. Our team is well-versed in various abrasive blasting techniques, including steel grit blasting and crushed glass abrasive blasting.

In addition to our expertise in abrasive blasting, we also offer a range of other services, including industrial coatings, protective coatings, and corrosion control. Our team is knowledgeable in the latest industry standards and regulations and can provide guidance and recommendations to ensure that each project meets the necessary requirements.

We also understand the importance of safety in the workplace. Our team follows strict safety protocols and uses state-of-the-art equipment to ensure each project is completed safely and efficiently. We are committed to maintaining a safe work environment for our team members and clients.

At Neumann Industrial Coatings, we believe that our professional expertise sets us apart from our competitors. We are dedicated to providing the highest quality services to our clients and ensuring their satisfaction with each project. Contact us today to learn more about our abrasive blasting and other services.

- Quality Assurance:

At Neumann Industrial Coatings, we take pride in providing our clients with high-quality abrasive blasting services. We understand that a quality finish is essential to the longevity of your equipment and structures. That’s why we have implemented a rigorous quality assurance process to ensure that every job we undertake meets or exceeds our client’s expectations.

Our quality assurance process begins with a detailed inspection of the surface to be blasted. Our team of experienced professionals assesses the surface and determines the most appropriate blasting method, the appropriate abrasive media, and the required pressure to achieve the desired result. Our team then creates a plan outlining the work scope and the necessary equipment, tools, and materials to achieve the desired finish.

Once the surface preparation is complete, we undertake a thorough inspection to ensure the surface is free of debris, contaminants, and any remaining coatings or rust. Our team then checks for surface profile and roughness, ensuring that the surface is correctly prepared for the next stage of the process.

During the coating application, we implement further quality assurance measures to ensure the coating is applied uniformly and to the correct thickness. We use various tools, including wet and dry film thickness gauges, to ensure the coating thickness is within the specified tolerance.

After the coating application is complete, we undertake a final inspection to ensure that the coating has been applied uniformly and to the correct thickness. Our team checks for defects, such as pinholes, sags, or runs, and rectifies any issues before completing the job.

We also provide our clients with comprehensive documentation, including a detailed report outlining the scope of work, the blasting and coating processes used, and the materials and equipment utilized. This documentation provides our clients peace of mind, knowing that the job has been completed to the highest possible standard.

In conclusion, we are committed to providing our clients with high-quality abrasive blasting services at Neumann Industrial Coatings. Our rigorous quality assurance process ensures that every job we undertake meets or exceeds our client’s expectations. We take pride in our work and believe our quality assurance process sets us apart from other blasting companies.

Conclusion:

In conclusion, abrasive blasting is a versatile and effective surface preparation method in various industries. Neumann Industrial Coatings offers a comprehensive range of abrasive blasting services using steel grit and crushed glass media. Our professional team has extensive experience determining the most appropriate method for each application, ensuring that the desired finish is achieved efficiently, cost-effectively, and with minimal environmental impact.

Our commitment to quality assurance is paramount, and we use the latest technology and equipment to ensure that every project is completed to the highest standards. We take pride in delivering exceptional results that meet or exceed our client’s expectations.

At Neumann Industrial Coatings, we understand the importance of deadlines, budgets, and safety. We work closely with our clients to ensure that their projects are completed on time, within budget, and with minimal disruption to their operations. Our focus on safety ensures that our team and client’s personnel are protected from harm during the abrasive blasting process.

In conclusion, if you need a reliable and professional abrasive blasting service, look no further than Neumann Industrial Coatings. Our expert team is ready to provide you with the highest quality abrasive blasting services tailored to your specific needs and requirements. Contact us today to discuss your project and discover how we can help you achieve the best possible results.

Removing Rust, Restoring Life

Introduction:

Rust is a common problem that affects metal surfaces, causing deterioration and weakening of the structure. Removing rust and providing protective coatings are crucial to ensure the longevity and durability of metal structures. One of the most effective methods of removing rust is abrasive blasting. However, the level of rust and the type of surface preparation required depends on the rust grade and class of blast cleaning, according to AS1627.9. Neumann Industrial Coatings is a professional abrasive blasting service provider that understands the importance of rust removal and surface preparation according to the appropriate standards.

Rust Grades:

According to AS1627.9, there are four different rust grades, each with its own set of guidelines for blast cleaning. These grades are based on the level of rust and corrosion present on a substrate surface and are identified as A, B, C, and D.

- Grade A is the least severe rust grade, with only light rust staining or discolouration present on the surface. The guidelines for blast cleaning this Grade require that the surface be cleaned to a minimum of Sa2.5, which means that all visible oil, grease, dust, dirt, rust, and other foreign materials must be removed from the surface. This level of cleaning is suitable for surfaces that will be painted or coated with a protective layer.

- Grade B is characterized by the presence of light to medium rust staining and a light coating of loose rust and scale. To achieve the necessary level of cleaning, the surface must be blasted to a minimum of Sa2.5. In addition, all tightly adhering rust and scale must be removed, leaving only slight staining or discolouration on the surface.

- Grade C is a more severe rust grade, with medium to heavy rust staining and a moderate coating of loose rust and scale. To achieve the necessary level of cleaning for this Grade, the surface must be blasted to a minimum of Sa2.5, with all tightly adhering rust and scale removed. In addition, all pitting and other visible surface defects must be removed, leaving only a slightly roughened surface.

- Grade D is the most severe rust grade, with heavy rust staining and a heavy coating of loose rust and scale. To achieve the necessary level of cleaning for this Grade, the surface must be blasted to a minimum of Sa3, which is a higher level of cleaning than for the other grades. In addition, all tightly adhering rust and scale must be removed, along with any pitting or other visible surface defects. The resulting surface should be uniformly roughened with a surface profile suitable for the intended coating system.

Classes of Blast Cleaning:

AS1627.9 specifies four classes of blast cleaning for steel surfaces, including Class 1, 2, 2.5, and 3. The classes represent the level of surface preparation required, depending on the rust grade. Class 1 is the least stringent, and Class 3 is the most stringent.

- Class 1: Light Blast Cleaning

Class 1 requires the removal of loose rust, mill scale, and other surface contaminants. The surface should have a minimum of 95% of the original surface profile. This class is suitable for surfaces with Grade A rust. - Class 2: Thorough Blast Cleaning

Class 2 requires the removal of all visible rust, mill scale, and other surface contaminants. The surface should have a minimum of 100% of the original surface profile. This class is suitable for surfaces with Grade B and C rust. - Class 2.5: Very Thorough Blast Cleaning

Class 2.5 is an intermediate class between Class 2 and Class 3. This class requires the removal of all visible rust, mill scale, and other surface contaminants. The surface should have a minimum of 125% of the original surface profile. This class is suitable for surfaces with Grade B and C rust, requiring higher surface preparation. - Class 3: Near-White Blast Cleaning

Class 3 is the most stringent surface preparation level, requiring removing all visible rust, mill scale, and other surface contaminants. The surface should have a minimum of 95% of the original surface profile. This class is suitable for surfaces with Grade C rust, where the surface needs to be prepared for high-performance coatings.

Neumann Industrial Coatings Services:

Neumann Industrial Coatings provides professional abrasive blasting services that adhere to AS1627.9 standards. Our team of experts can determine the appropriate class of blast cleaning required for each surface, depending on the rust grade. We use different abrasive blasting media, including steel grit and crushed glass, to prepare the desired surface. Our state-of-the-art equipment and professional expertise ensure that we provide efficient and cost-effective services.

Conclusion:

Rust can cause significant damage to metal structures, but abrasive blasting is a highly effective method of removing rust and preparing surfaces for protective coatings. It is essential to understand the rust grade and class of blast cleaning required for each surface to achieve optimal results. Neumann Industrial Coatings is a professional abrasive blasting service provider that adheres to AS1727.9 standards to provide efficient and cost-effective services. Removing rust and restoring life is our motto.

Prioritising Safety in Abrasive Blasting

The Abrasive Blasting Code of Practice 2013 (the Code) is a set of guidelines issued by Workplace Health and Safety Queensland to provide practical advice on managing the risks associated with abrasive blasting. The Code provides a framework for employers and workers to manage the risks associated with abrasive blasting activities and ensure that their work practices comply with relevant health and safety legislation. In this review, we will examine the key components of the Code, including its scope, purpose, and requirements, as well as its strengths and weaknesses.

Scope and Purpose of the Code

The Code applies to all abrasive blasting activities conducted in Queensland, including those carried out in the construction, mining, and manufacturing industries. Its main purpose is to guide employers and workers in identifying, assessing and controlling the risks associated with abrasive blasting. The Code outlines a series of best practice guidelines that should be followed to ensure that abrasive blasting activities are carried out in a safe and controlled manner.

Requirements of the Code

The Code outlines a series of requirements that must be met by employers and workers engaged in abrasive blasting activities. These include:

- Risk Management – Employers must conduct a risk assessment to identify the hazards associated with abrasive blasting activities and implement measures to control those hazards.

- Competency – Employers must ensure that all workers involved in abrasive blasting activities are competent and trained to perform their tasks safely.

- Control Measures – Employers must implement control measures to minimise the risks associated with abrasive blasting, including using personal protective equipment (PPE) and engineering controls to minimise exposure to dust and noise.

- Environmental Protection – Employers must take steps to minimise the environmental impact of abrasive blasting activities, including the containment and disposal of blasting debris and using environmentally friendly blasting media where possible.

Strengths of the Code

The Code provides clear and concise guidance on the best practices for managing the risks associated with abrasive blasting. It outlines the specific requirements that employers and workers must meet engaged in abrasive blasting activities and provides practical advice on implementing those requirements. The Code’s focus on risk management is particularly commendable, as it highlights the importance of identifying, assessing, and controlling the hazards associated with abrasive blasting.

The Code also emphasises the importance of competency and training, essential for ensuring that workers have the skills and knowledge to perform their tasks safely. The inclusion of specific requirements for environmental protection is also a strength of the Code, as it recognises the need to minimise the environmental impact of abrasive blasting activities.

Weaknesses of the Code

One weakness of the Code is that it is not legally binding, and compliance with its requirements is voluntary. While the Code provides guidance on best practices, it does not have the same legal weight as legislation, which may limit its effectiveness in promoting safe and responsible abrasive blasting practices.

Another weakness of the Code is that it does not provide detailed guidance on specific aspects of abrasive blasting, such as the selection and use of blasting media. While the Code recommends the use of environmentally friendly blasting media, it does not provide specific guidance on how to select or use these media, which may limit its usefulness to employers and workers.

Conclusion

Overall, the Abrasive Blasting Code of Practice 2013 is a valuable resource for employers and workers engaged in abrasive blasting activities in Queensland. The Code provides clear and concise guidance on best practices for managing the risks associated with abrasive blasting. It emphasises the importance of risk management, competency and training, and environmental protection. While the Code is not legally binding and has some weaknesses, it is an essential tool for promoting safe and responsible abrasive blasting practices. It should be used in conjunction with relevant health and safety legislation.

Final Note: Don’t let Abrasive Blasting leave you feeling Sand-Blasted!

Abrasive Blasting: Because Sometimes Soap and Water Just Won’t Cut It

Compressed air abrasive blast cleaning is a powerful method of cleaning surfaces. Combining an abrasive or abrasive mixture with high-velocity air can effectively remove rust, paint, and other surface contaminants. This essay will delve into the details of compressed air abrasive blast cleaning, discussing its benefits and limitations.

Methodology:

The compressed air abrasive blast cleaning method is widely used in various industries for cleaning and surface preparation. The method involves using compressed air to direct an abrasive material onto a surface, which removes contaminants such as rust, paint, and scale. The abrasive material is usually a mixture of materials such as sand, garnet, glass beads, aluminium oxide, or steel shot. The abrasive material is injected into the air stream from a pressurised container, where it mixes with the air stream and is propelled onto the surface being cleaned.

The process of compressed air abrasive blast cleaning involves the following steps:

- Surface preparation: Before beginning the cleaning process, the surface must be prepared by removing any loose materials such as paint, rust, or scale. This can be done using scraping, wire brushing, or power tool cleaning.

- Abrasive selection: The type of abrasive material selected for the cleaning process will depend on the type of surface being cleaned and the desired level of cleaning. Different types of abrasive materials have varying levels of aggressiveness. They can be selected based on factors such as the surface material, the level of contamination, and the required surface profile.

- Abrasive mixing: The selected abrasive material is then mixed with compressed air and directed through a nozzle onto the surface being cleaned. The air pressure and the type of nozzle used can be adjusted to achieve the desired level of cleaning.

- Dust suppression: The compressed air abrasive blast cleaning process can generate significant amounts of dust, which can be a safety hazard for workers and can also pose an environmental risk. Dust suppression techniques such as water spraying or vacuum extraction can minimise the dust generated during the cleaning process.

- Waste disposal: The waste generated from the compressed air abrasive blast cleaning process, including the spent abrasive material and any removed contaminants, must be disposed of in accordance with environmental regulations.

The compressed air abrasive blast cleaning method is suitable for many applications, including cleaning and preparing surfaces for painting, removing rust and scale from metal surfaces, and cleaning concrete and masonry surfaces. The method can be used on large structures such as bridges, ships, and tanks, as well as on smaller objects such as pipes and valves. The method can be used continuously or intermittently and can be designed to allow for abrasive recovery, cleaning, and recycling, which can help reduce waste and costs.

Suitability:

Compressed air abrasive blast cleaning is suitable for cleaning work of all types, including large structures having variable rust grades. This method is an effective way to remove rust, paint, scale, and other surface contaminants. It can be used on various surfaces, including steel, concrete, and brick.

This method of cleaning is particularly suitable for industrial and commercial applications where large structures need to be cleaned in a timely and efficient manner. It is also commonly used in the marine industry to clean the hulls of ships and boats.

Compressed air abrasive blast cleaning can also be used in enclosed plants, rooms, or cabinets, making it suitable for use in confined spaces. This is particularly important in industries such as aerospace and automotive, where precision cleaning is necessary for small and intricate parts.

However, it is important to note that compressed air abrasive blast cleaning may not be suitable for all applications. Its use may be restricted by environmental or legislative requirements, in which case dust suppression or collection facilities are required.

Furthermore, this method is not suitable for removing oil, grease, and related contaminants, nor will it remove chemicals such as soluble salts. Additional treatment is required if the removal of such contaminants is necessary.

It is important to carefully evaluate the suitability of compressed air abrasive blast cleaning for each specific application before proceeding with the method. Factors such as the type of surface to be cleaned, the type and level of contaminants to be removed, and the environment in which the cleaning will take place must all be considered.

Overall, compressed air abrasive blast cleaning is a highly effective method for cleaning a variety of surfaces and structures. However, its suitability must be evaluated on a case-by-case basis, considering each application’s specific needs and requirements.

Limitations:

As with any industrial process, compressed air abrasive blast cleaning has limitations and may not be suitable for every cleaning application. Here are some of the limitations to keep in mind when considering the use of compressed air abrasive blast cleaning:

Dust generation: The process of compressed air abrasive blast cleaning can generate a significant amount of dust, which may pose a health hazard to workers and may also create environmental concerns. In certain situations, dust suppression or collection facilities may be necessary to minimise the impact of dust generated by the process.

Limited effectiveness in removing certain types of contaminants: While compressed air abrasive blast cleaning is highly effective in removing rust, corrosion, and other surface contaminants, it is ineffective in removing oil, grease, and related contaminants. It also cannot remove soluble salts or other types of chemical contamination from surfaces.

Potential damage to delicate surfaces: Compressed air abrasive blast cleaning can be a harsh process and may cause damage to delicate surfaces, including thin metals and softer materials. Careful consideration must be given to the type of abrasive used and the pressure at which it is applied to avoid damaging surfaces.

Noise: The use of compressed air abrasive blast cleaning can produce high levels of noise, which may pose a hazard to workers and require the use of hearing protection.

Regulatory restrictions: The use of compressed air abrasive blast cleaning may be subject to regulatory restrictions and environmental regulations. It is important to ensure the process complies with applicable regulations before beginning any cleaning project.

Overall, compressed air abrasive blast cleaning can be a highly effective method of cleaning surfaces, particularly for the removal of rust, corrosion, and other surface contaminants. However, it is important to carefully consider the suitability of the method for a given cleaning project and to address any potential limitations before beginning the process.

Benefits:

The benefits of compressed air abrasive blast cleaning are numerous. First and foremost, this method is highly effective at removing surface contaminants, such as rust, paint, and other coatings, from a variety of surfaces. Unlike other cleaning methods, compressed air abrasive blast cleaning can be used on large structures with varying degrees of rust and corrosion. This makes it an ideal method for industrial settings, such as factories and shipyards.

Additionally, compressed air abrasive blast cleaning is a versatile method that can be used in a variety of settings. It can be performed in enclosed spaces, such as cabinets or rooms, or open areas. The flexibility of this method allows it to be used in various industries, including manufacturing, construction, and automotive.

Another significant benefit of compressed air abrasive blast cleaning is its ability to recycle and reuse abrasive materials. By using a pressurised container to inject the abrasive material into the air stream, the abrasive can be easily recovered, cleaned, and reused. This not only saves time and money, but it also reduces the amount of waste generated by the cleaning process, making it a more environmentally friendly method.

Compressed air abrasive blast cleaning is also a relatively fast and efficient cleaning method. The high-velocity air/abrasive flow can quickly remove surface contaminants, allowing for faster turnaround times and increased productivity. Additionally, the use of dust suppression or collection facilities can further improve the efficiency of the process by reducing the amount of dust generated.

Finally, compressed air abrasive blast cleaning is a cost-effective method of cleaning. While there may be initial costs associated with purchasing equipment and setting up the necessary infrastructure, the ability to recycle and reuse abrasive materials, as well as the efficiency and speed of the process, can ultimately result in significant cost savings over time.

The benefits of compressed air abrasive blast cleaning make it a highly effective and versatile method of cleaning for a variety of industries and settings. Its ability to remove surface contaminants, recycle and reuse abrasive materials, and improve efficiency and productivity make it a popular choice for industrial cleaning applications.

Conclusion:

In conclusion, compressed air abrasive blast cleaning is a highly effective method for removing surface contaminants and preparing surfaces for further treatment or coating. It is versatile and suitable for various applications, including large structures with variable rust grades, and can be used on-site and in enclosed environments. The system can also be designed for abrasive recovery, cleaning, and recycling, which can reduce waste and save costs.

However, as with any method, there are limitations and potential risks associated with compressed air abrasive blast cleaning. These include the generation of dust, which may be harmful to workers and the environment, and limitations in removing certain types of contaminants, such as oils, grease, and soluble salts. It is important to carefully assess the suitability of compressed air abrasive blast cleaning for a given application and ensure proper safety measures and environmental regulations are followed.

Overall, when used appropriately and with the necessary precautions in place, compressed air abrasive blast cleaning can be a highly effective method for surface preparation and cleaning. It is a valuable tool for industries such as construction, manufacturing, and maintenance, where the quality of surface preparation and cleaning is critical for the success of subsequent processes. By understanding its benefits, limitations, and risks, companies can make informed decisions about whether compressed air abrasive blast cleaning is the right method for their specific needs and how to use it safely and effectively.

Final Thoughts:

Compressed air abrasive blast cleaning effectively cleans surfaces, removes rust, and prepares surfaces for coating. It has its limitations and requires proper precautions to be taken to ensure safety and environmental compliance.

Neumann Industrial Coatings has extensive experience in surface preparation and coating application. We have the expertise and equipment required to perform compressed air abrasive blast cleaning safely and effectively. Our team is trained in all aspects of surface preparation, including the selection of appropriate abrasives, proper equipment operation, and environmental compliance.

At Neumann Industrial Coatings, we understand the importance of surface preparation in achieving a successful coating application. We take great care in ensuring that all surfaces are properly cleaned and prepared before applying coatings to ensure maximum adhesion and longevity.

In addition to compressed air abrasive blast cleaning, we offer various surface preparation methods, including power tool cleaning, high-pressure water cleaning, and abrasive blasting using various media. Our experienced team will work with you to determine the best surface preparation method for your specific project.

Contact us today to learn more about our surface preparation and coating services and how we can help you achieve a successful coating application.

Get your surfaces ready for a perfect finish with ISO 8504-2 Part 2 Abrasive Blast-Cleaning

Introduction:

Abrasive blast-cleaning is an essential process in surface preparation that involves using abrasive materials to remove rust, paint, and other contaminants from a surface. ISO 8504-2 Part 2 is a comprehensive standard that provides guidelines for abrasive blast-cleaning, including the selection of abrasives, surface preparation, and the measurement of surface cleanliness. This standard is critical to ensuring that the surfaces of structures and equipment are adequately prepared for coating applications, which is crucial for the longevity and integrity of the coating system.

Scope:

ISO 8504-2 Part 2 provides guidance on preparing steel substrates before applying paints and related products. This standard applies to the blast-cleaning of new or previously coated steel surfaces and outlines the requirements for surface preparation by abrasive blast-cleaning.

General Principles:

This section of the standard provides an overview of the principles of abrasive blast-cleaning, including the objectives of the process, the types of abrasives used, and the factors that affect the performance of the process.

Surface Preparation:

Surface preparation is a critical step in achieving optimal coating performance. This section of the standard provides detailed guidance on the various surface preparation methods, including abrasive blast-cleaning. It outlines the requirements for surface cleanliness, surface roughness, and the removal of contaminants.

Abrasive Blast-Cleaning:

The abrasive blast-cleaning section of the standard provides comprehensive guidelines on selecting abrasives, including their properties, particle size, and shape. It also outlines the requirements for blast-cleaning equipment, including the types of nozzles, hoses, and compressors that should be used.

Inspection and Quality Control:

This section of the standard provides guidelines on the inspection of blast-cleaned surfaces, including the visual assessment of surface cleanliness, surface roughness, and the removal of contaminants. It also includes information on the measurement of surface cleanliness using various methods, such as the use of test patches, dust tape, and surface comparators.

Conclusion:

ISO 8504-2 Part 2 is a comprehensive guide that outlines the best practices for achieving optimal surface preparation through abrasive blast-cleaning. By following the guidelines set out in this standard, coating professionals can ensure that surfaces are adequately prepared for the application of coatings, which is crucial for the longevity and integrity of the coating system.

Final Thoughts:

At Neumann Industrial Coatings, we understand the importance of surface preparation in achieving a successful coating application. Our team of experts is trained in the latest surface preparation techniques, including abrasive blast-cleaning, and we adhere to the guidelines set out in ISO 8504-2 Part 2 to ensure that our clients receive the highest quality coating application possible.

Contact us today to learn more about our services and how we can help you achieve the perfect surface finish.