The Term “Sand” in Sandblasting

Sandblasting is a very general term which is used to describe the process of propelling very small bits of material at high speed to clean or etch a surface. Sand (silica sand, beach sand, river sand) used to be commonly used for sandblasting, hence the term “Sand Blasting”, but silica sand breaks up easily causing large amounts of dust, which exposes the operator to silicosis, a debilitating lung disease, which is caused by the extended inhalation of the dust created by the use of silica sand as a sandblasting media.

The use of silica sand as an abrasive media in sandblasting is banned in many countries, including Australia, and is now recognized world-wide as a Class 1 Carcinogen.

Sandblasting Media

However other materials can be safely used in place of silica sand. At Neumann Industrial Coatings – Abrasive Blasting, we predominately use steel grit, for removing rust and layers of paint from thick metal surfaces, and crushed glass, for lighter surface which could be damaged using other heavier media.

Other types of media that are available includes: steel shot, steel grit, aluminium oxide, copper slag, crushed glass grit, glass beads, silicon carbide, plastic, pumice, corn cob, walnut shells, and many others. But there are still dangers in inhaling the fine dust particles during the process. Abrasive blasting or sandblasting is carefully controlled, and we always use alternate air supply, protective clothing, and proper ventilation when sandblasting.

The Process

Very simply, the abrasive blasting (sandblasting) process consists of three components: the abrasive media, compressed air, and a blasting nozzle. At our Abrasive Blasting Facility in Currumbin we predominately use abrasive blasting (sandblasting) to clean metal objects of rust and paint prior to painting. But sand blasting can also be used, by others for etching and small object cleaning.

The History of Sandblasting

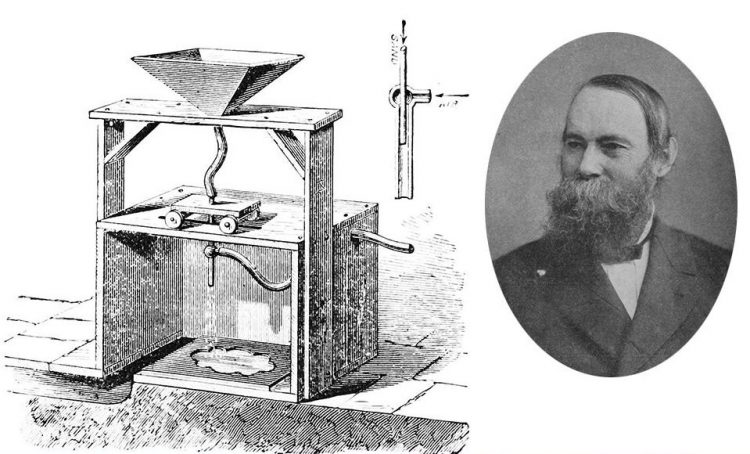

The sandblasting process was first patented in the US in 1870, after the observation of how sand-laden winds affected objects they came in contact with, by Tilghman a chemist from Philadelphia, who also invented the air compressor. The 1870 patent by Tilghman was described as:

“A shot stream hurled to high speed by a steam or a draught is used as a tool to cut the stone and other materials. If it is hurled to a lower speed, it is used to grind down and ornament the glass surface.”

1886 saw Gutmann build the first suction sandblasting machine. He later patented the “compressed air sandblaster” in 1893.

1886 saw Gutmann build the first suction sandblasting machine. He later patented the “compressed air sandblaster” in 1893.

Phone : (07) 5589 9303 or (07) 5589 9746 Mobile 0429 468 631